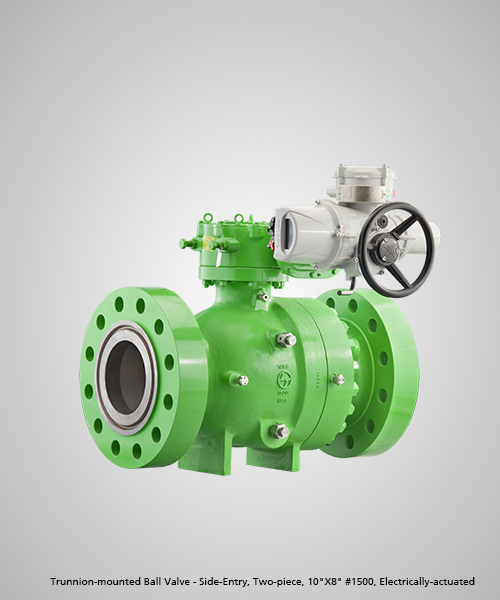

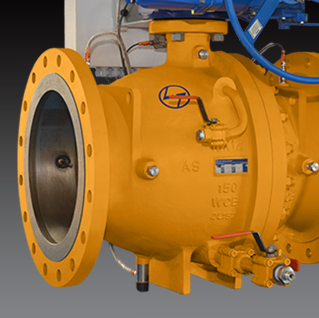

L&T Valves Limited Trunnion Mounted Ball Valves are of 2-piece / 3-piece design, with flanged or butt-weld ends.

As a standard, the valves are manufactured in bolted body designs, where the joint between the body and the connector is bolted. The bolted body design offers flexibility for dismantling during field service in case of an emergency.

Welded body designs, where the joint between the body and connector is welded, are also available on request

Features

Trunnion-mounted Ball Valves

Size 2″ to 56″ | ASME Class Class 150 to 2500

API 6D | API 608

2 Piece/3 Piece Construction | Full/Reduced bore

Side Entry & Top Entry | Soft Seat & Metal seat

Bolted & Welded | Flanged & Buttweld Design

- Trunnion-mounted Ball Valve design complies to API 6D and can be offered with API 6D monogram

- Wide range of product portfolio in Side-entry and Top-entry designs

- Valves successfully tested to Shell Design Evaluation Test, Procedure 77/300 for temperature -29 to 150 degree C (O rings) and -50 to 150 degree C (Lip seals)

- Vaves for gas services can be supplied with High pressure gas test (Sniffing & Immersion Method)

- Coil springs used for consistent seat loading and lower operating torque

- Double block and bleed (DBB) feature – Valves are designed and tested for automatic cavity relief

- Lip seals are provided for low temperature services & Cryogenic services

- 2/3 stage Stem and 2 stage Body Joint sealing system; Primary O ring and Secondary graphite (in 3 stage stem, thrust washer is primary)

- Where tight shut off is required, Double piston effect (DPE) seats provided for redundancy in sealing