Special Features & Benefits

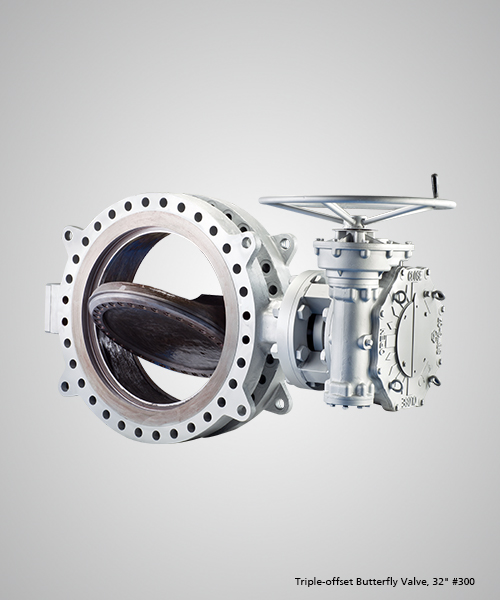

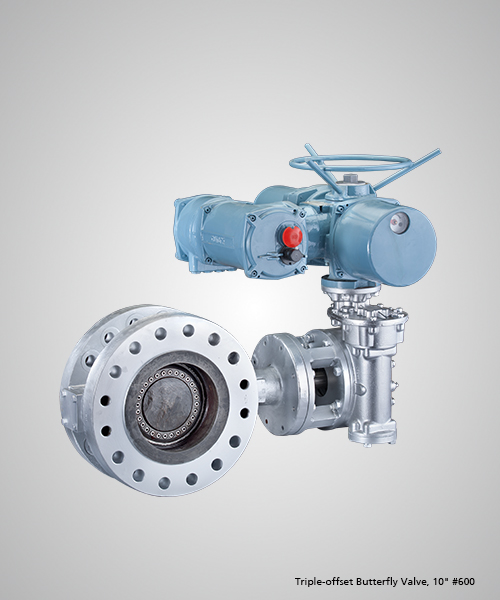

Design complies to API 609

Valves offered with API 609 monogram

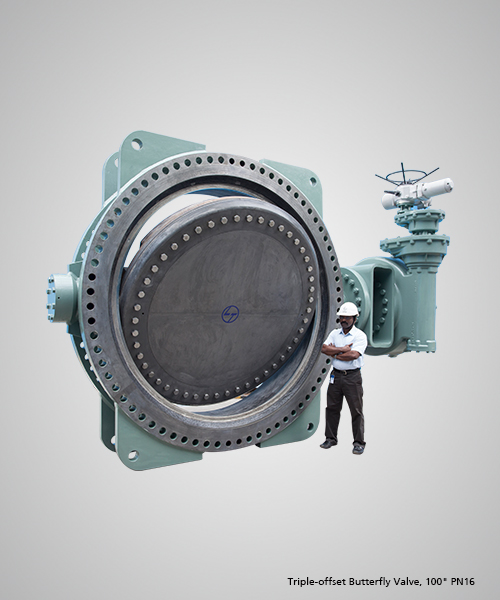

Wide portfolio of Short-pattern and Long-pattern valves

Design Validation Test – 12” Class 150 valve successfully completed 10,000 cycles

Fugitive emissions – Complies to ISO 15848-1 Endurance Class CO2 and Tightness class AH

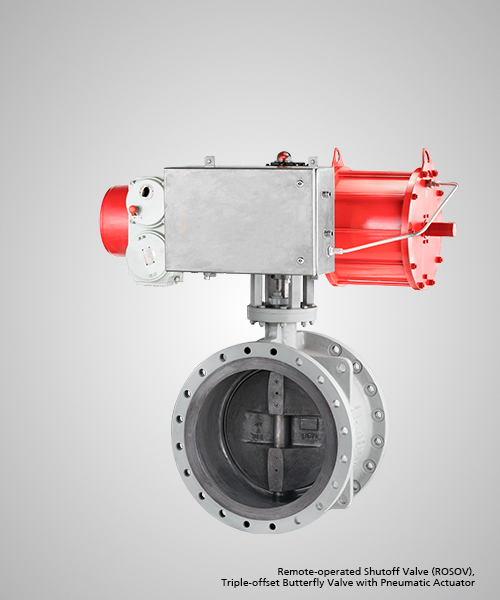

Fire safe by design and complies to API 607/ ISO 10497 (preferred and non-preferred direction)

API RP 591 test conducted on 12” Class 150 TOBV at Element Lab, USA

CE Marking – Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H

PED Module B1 Design examination certificate (certified by DNV) available

Atex – Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment

SIL3 Safety Integrity Level to IEC 61508

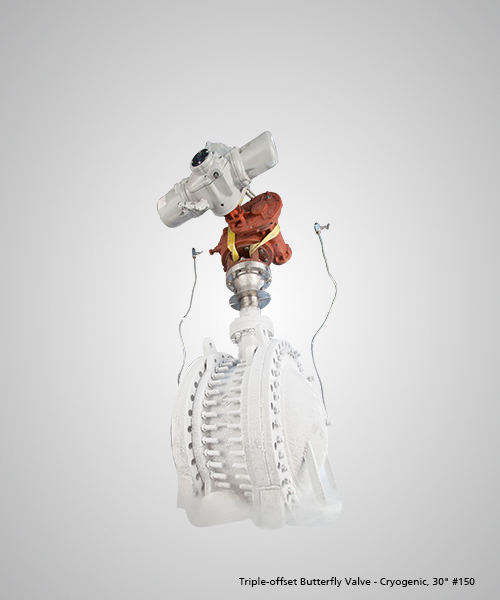

Triple-offset Geometry minimises seat-seal contact – lower operating torque and cost of ownership

Compact and light weight as compared to gate valves of the same size

Hard faced in-situ body seat and flexible laminar seal ensure bubble tight sealing

Single piece Anti blow out shaft

Disc contour ensures mimimum turbulence and pressure drop

Retainer bolting complies to ASME Section VIII Div 1 Appendix 2